30+ Best private label coffee manufacturers & suppliers for your brand

Join Wonnda and get access to our exclusive supplier directory with a curated list of private label coffee manufacturers & suppliers.

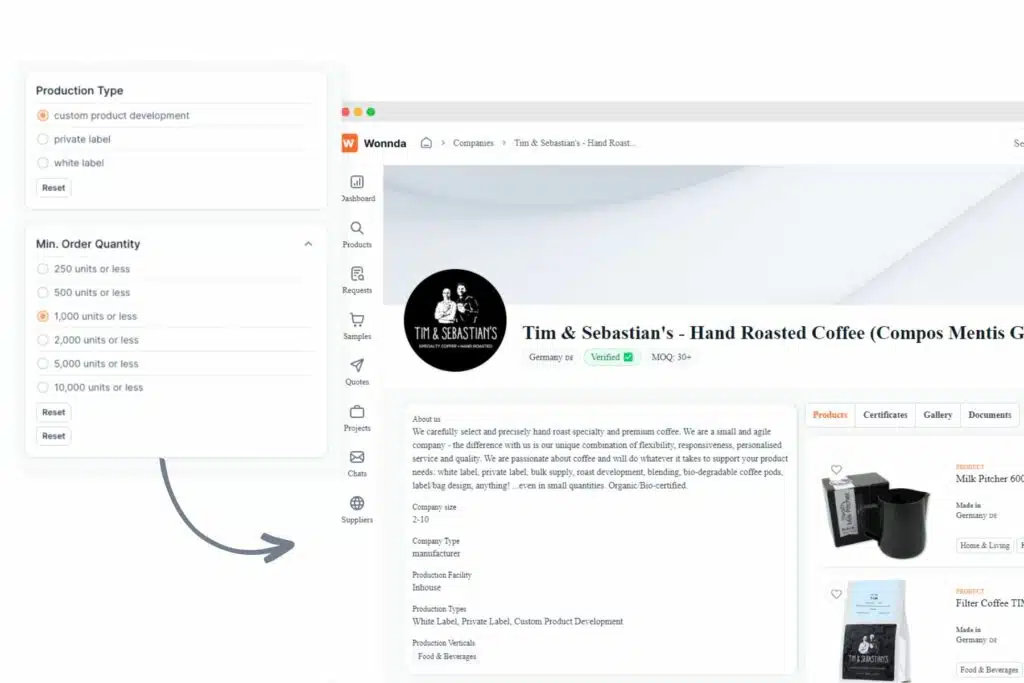

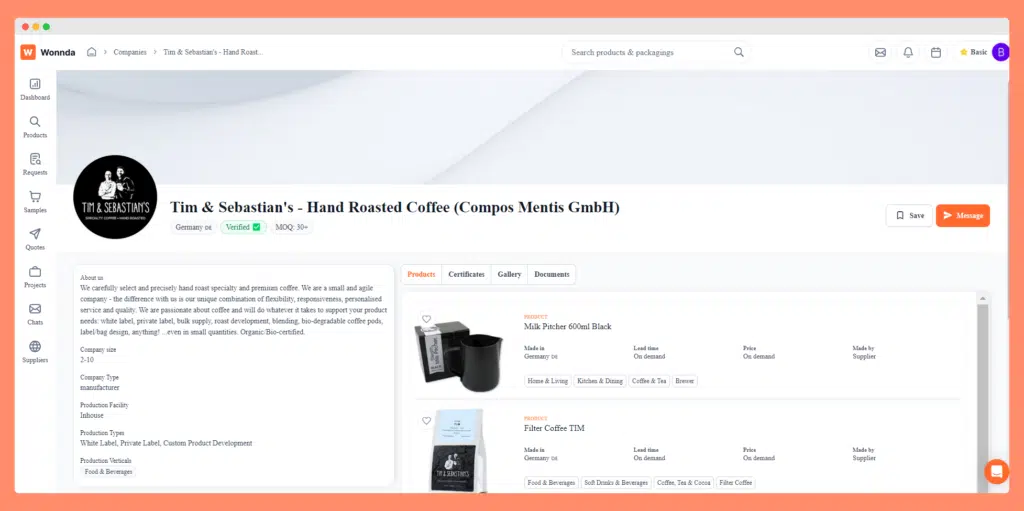

1. Tim & Sebastian's - Hand Roasted Coffee - Germany

They carefully pick and roast special and premium coffees. As a small team, they stand out for being flexible, quick to respond, and offering personalized care and top-notch coffee.

They’re all about loving coffee and meeting any need you might have, including different labels, bulk orders, creating new roasts, mixing, eco-friendly pods, and designing labels and bags.

Access prices, minimum quantities and more by getting in contact with Tim & Sebastian’s – Hand Roasted Coffee via Wonnda.

2. Ellecaffè srl - caffè Janus - Italy

Since 1996, they’ve been a well-known coffee roasting company in Italy. They offer a wide variety of roasted coffee including beans, pods, capsules, cold brew, and coffee powder. Additionally, they provide private label services to meet different branding needs.

Signup at Wonnda to access more private label coffee suppliers, get quotes, see prices and minimum order quantities.

Sign up to access all private label coffee manufacturers

Use your business email address. The email will be used to create a free account. No credit card required. By signing up, you are accepting our terms & conditions & privacy policy.

Launching Your Private Label Coffee Business: A Step-by-step Guide

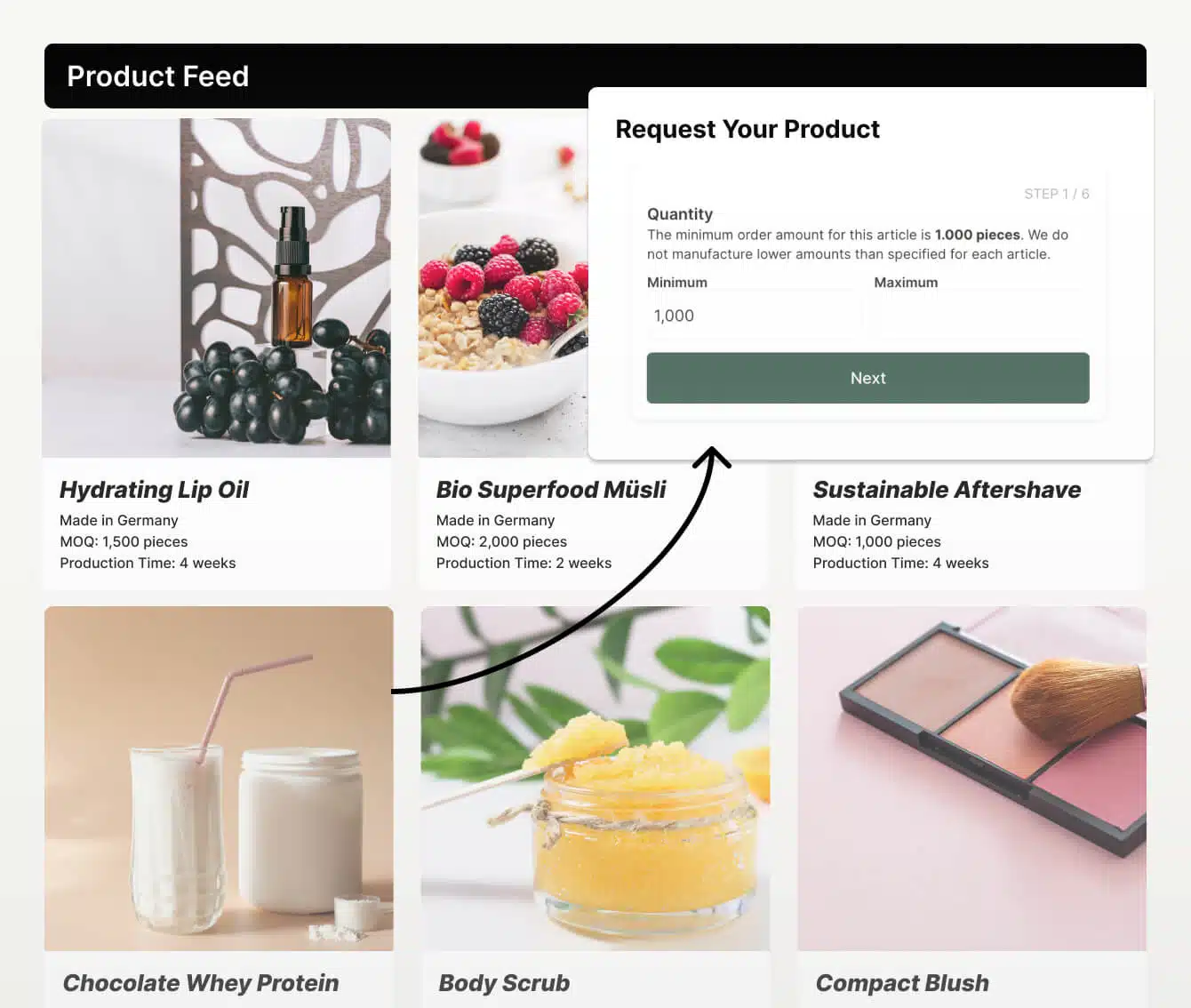

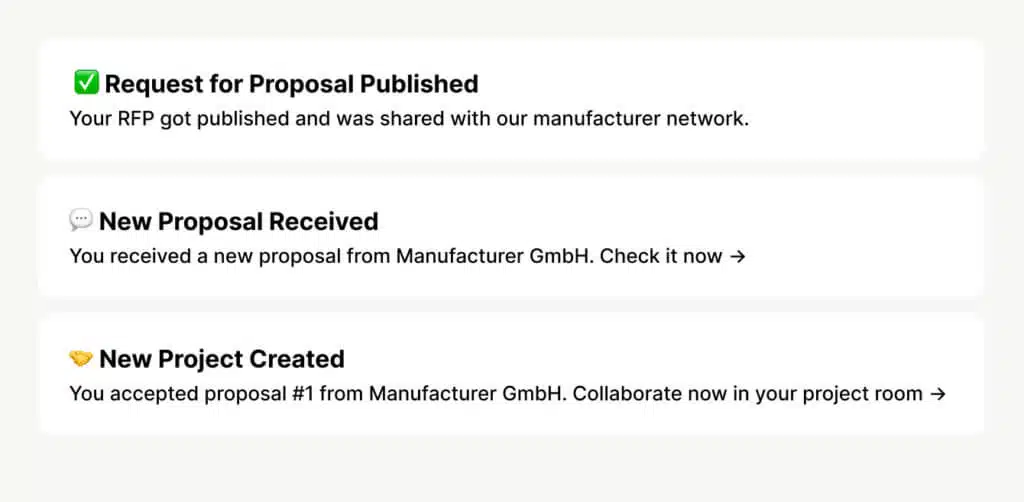

To help you navigate the course of launching your private label coffee business, we’ve designed a step-by-step guide. Consider leveraging the power of Wonnda – a digital tool connecting brands with leading manufacturers – to ease your sourcing and launch processes.

1. Carve Your Niche and Define Your Target Audience

The first step is defining your unique niche within the coffee industry and understanding your target audience’s preferences. This approach helps distinguish your brand from competitors and allows you to cater to your audience’s specific tastes effectively. Factors to consider include the type of coffee you plan to offer (single-origin, blends, flavored, etc.), roast profiles, and unique selling propositions.

2. Source Superior Quality Coffee Beans

When it comes to launching your private label coffee business, the quality of coffee beans you source plays an instrumental role. Align your brand’s identity and target market with the quality and type of coffee beans you plan to use. Prioritize collaborating with suppliers known for sustainable and ethical sourcing practices—elements increasingly significant to contemporary consumers.

3. Choose an Experienced Roasting Partner For Your Coffee Business

The importance of finding a reliable roasting partner for your coffee business cannot be overstated. Such a partner should have substantial industry experience, advanced roasting capabilities, and an unwavering commitment to maintaining quality and safety standards. Establishing open and efficient lines of communication with your roasting partner is crucial to ensure that your product quality consistently meets your specifications.

4. Develop a Unique Brand Identity

Your brand identity is the heartbeat of your private label coffee business. It’s made up of elements like your brand name, logo, and packaging design, and it tells your brand’s unique story. Working with a skilled designer can help you shape a strong and catchy brand identity. This identity should not only connect with your target audience but also set you apart from the competition. The right brand identity can make your coffee brand unforgettable and turn casual customers into loyal followers.

5. Strategize Your Marketing and Distribution of Private Label Coffee

To successfully launch your private label coffee business, developing a comprehensive marketing and distribution strategy is pivotal. This may entail establishing a strong online presence through a compelling website and engaging social media platforms, participating in trade shows and industry events, and partnering with retailers or distributors to extend your reach. Tailor your marketing efforts to your target market, employing techniques such as content marketing, influencer partnerships, and targeted advertising to boost brand visibility and stimulate sales.

6. Adhere to Regulations and Certifications

Before you set out on the journey of launching your private label coffee business, ensure strict compliance with relevant food safety regulations and certifications, such as HACCP, ISO, or BRC. Acquiring these certifications testifies your commitment to quality and safety, thus instilling trust among consumers and retail partners.

7. Monitor and Optimize Your Coffee Business Regularly

After you’ve launched, it’s essential to keep a close eye on your business operations. Analyzing performance metrics and looking for areas to improve should become routine activities. This involves regularly checking on your supply chain, digging deep into sales data, and actively seeking customer feedback. By understanding what’s working and what needs to be tweaked, you can pivot effectively and optimize your operations. Additionally, this process enables you to stay on top of changing market trends and customer preferences. All this helps you maintain a competitive edge in the market while continuing to provide value to your customers.

In essence, launching your private label coffee business involves a host of significant steps—from sourcing top-notch beans using Wonnda’s platform to partnering with a reliable roaster, from establishing a powerful brand identity to crafting robust marketing and distribution strategies. By diligently following these steps, you’ll lay a solid foundation for your venture and set your brand on the path of long-term success.

Frequently asked questions

What is a private label coffee?

A private label coffee is coffee that’s roasted and packaged by one company but branded and sold under another company’s or retailer’s brand name. This allows businesses to sell coffee as their own brand without having to invest in the roasting and manufacturing process.

What is the difference between private label and white label coffee?

The difference between private label and white label coffee lies in branding and customization. Private label coffee is customized to the seller’s specifications, allowing for unique blends, packaging, and branding tailored to their brand identity. White label coffee, however, involves a standard product produced by the manufacturer and sold to various retailers who then brand it as their own, with limited customization options beyond the packaging design.

What range of coffee products can you produce under a private label?

Under a private label, you can produce a wide range of coffee products including whole beans, ground coffee, single-serve pods or capsules compatible with popular brewing systems, cold brew concentrates, and specialty coffee powders for instant brews. The specific offerings can be tailored to meet your brand’s needs and customer preferences.

How customizable are the packaging options for private label coffee?

The packaging options for private label coffee are highly customizable, allowing brands to choose from a variety of materials, designs, and sizes to best suit their brand identity and customer preferences. Options typically include traditional bags, single-serve pods or capsules, bulk bins for whole beans, and specialty packaging for gift sets or sample packs. Brands can also customize packaging with their logos, colors, and marketing messages to enhance brand recognition and appeal to their target audience.

Where do I find the best private label coffee manufacturers?

To find the best private label coffee manufacturers, you can start with online platforms like Wonnda, which connects brands with a network of verified manufacturers specializing in private label products, including coffee. Wonnda simplifies the process of finding and partnering with manufacturers that align with your quality standards and production needs, making it easier to launch or expand your private label coffee line.

Are there any minimum order quantities for private label coffee?

Yes, private label coffee manufacturers typically have minimum order quantities (MOQs), which can vary significantly depending on the manufacturer and the specific product type. MOQs ensure the production process remains efficient and cost-effective. It’s important to discuss MOQs upfront with any potential manufacturer to ensure they align with your business needs and scale.