Contract Manufacturing

The best contract manufacturers for your business needs

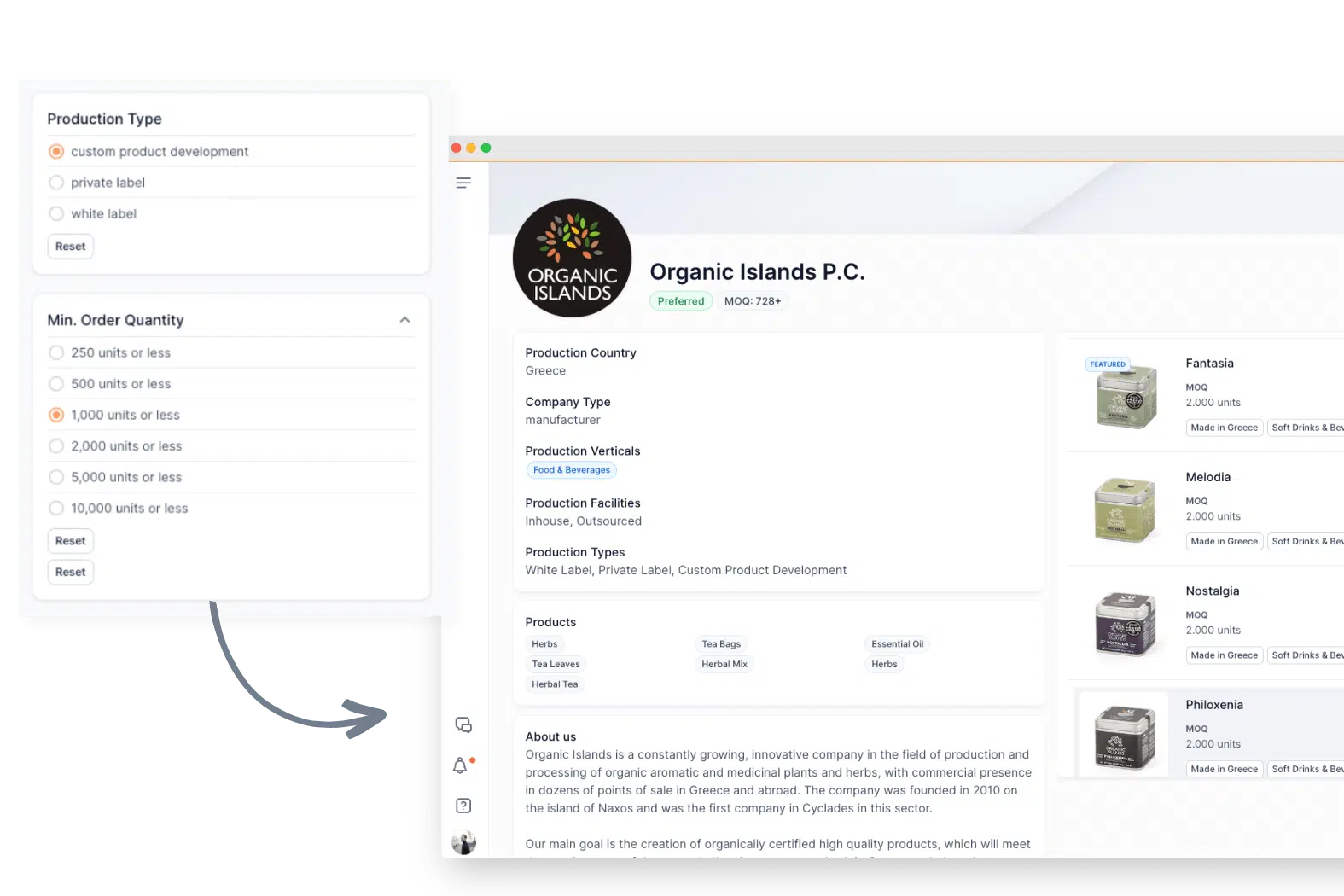

Explore verified contract manufacturers effortlessly through Wonnda. Our digital platform links you with vetted contract manufacturers (primarily in Europe). The contract manufacturing categories include beauty, food, supplements, apparel, and more. With Wonnda, turning your project concepts into high-quality products is simple and effective.

- Direct access to 8.000+ contract manufacturers on Wonnda

- 8.000+ buyers trust wonnda

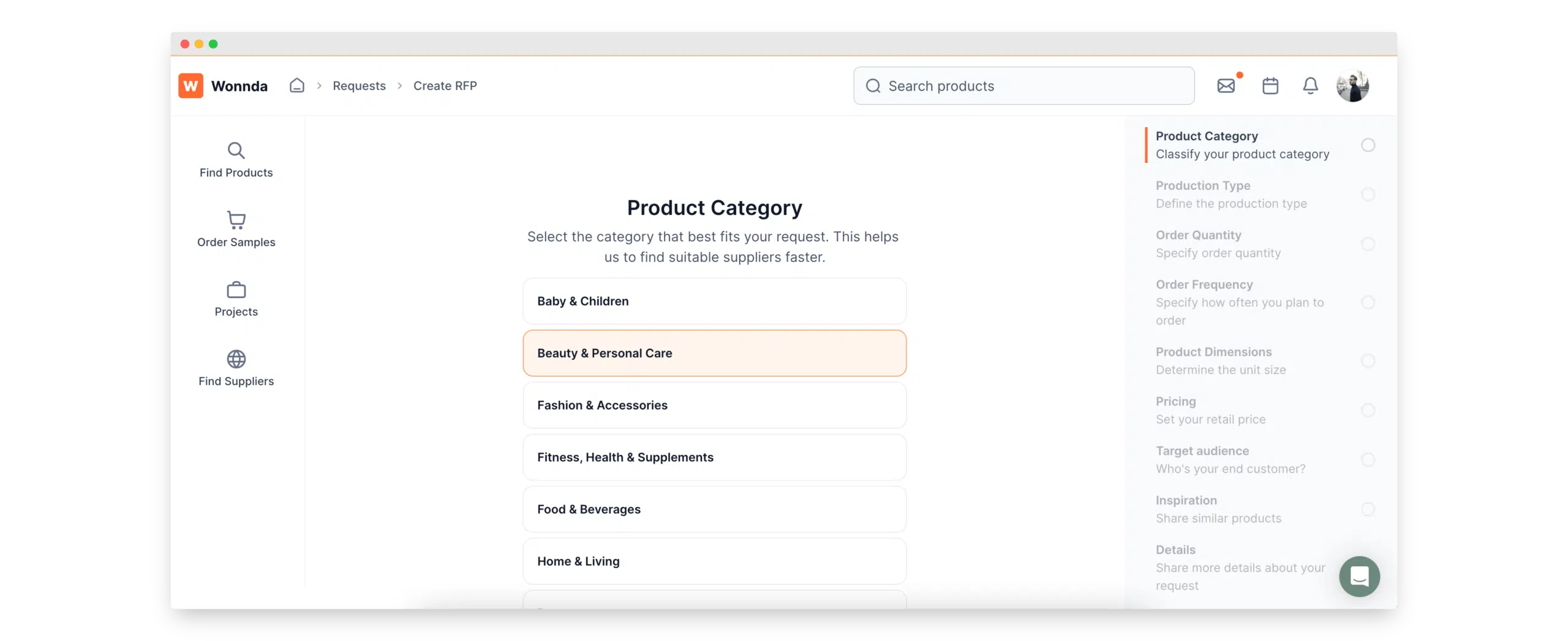

- Get quotes via our RFP feature

Why choose contract manufacturing through Wonnda?

Experience the advantages of contract manufacturing through Wonnda. Our platform ensures Quality Assurance by granting access to vetted manufacturers known for their high-quality production standards.

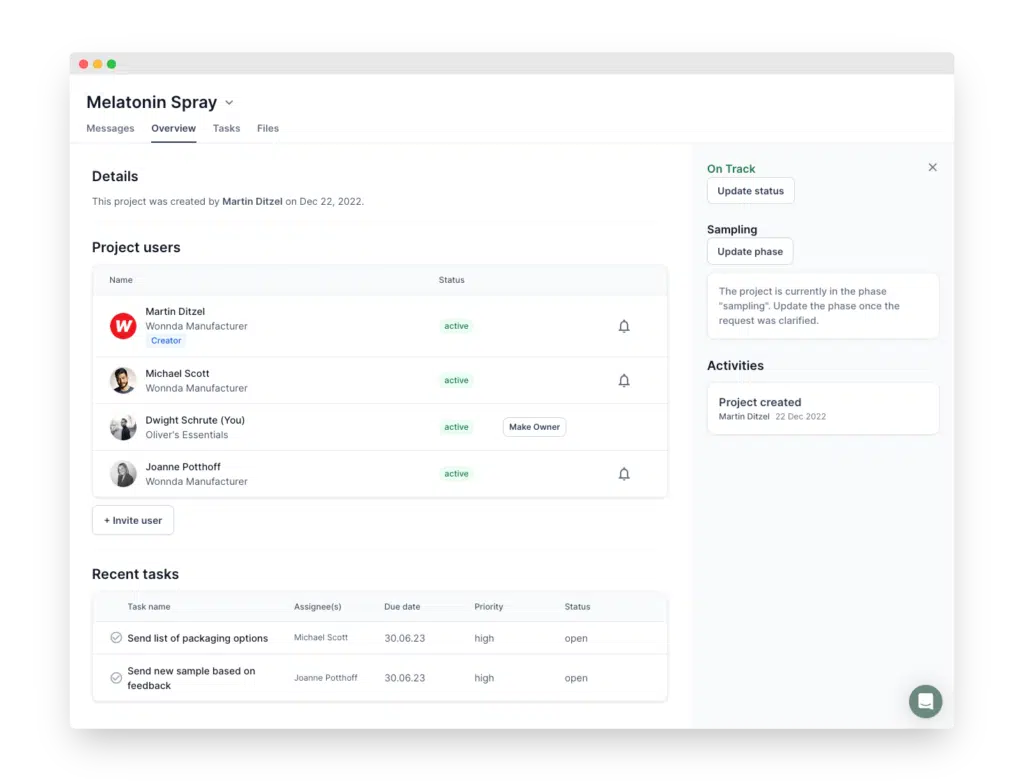

Enjoy Cost Efficiency through competitive pricing, made possible by direct connections with manufacturers, eliminating middlemen. Additionally, Time-Savings is a key benefit; our digital end-to-end solution significantly accelerates the product launch process, allowing you to move swiftly from concept to market. With Wonnda, every facet of contract manufacturing is designed to be seamless, economical, and efficient.

- Verified suppliers & manufacturers for your brand

- Directly work with manufacturers, no middleman

- Faster lead times & fully digital sourcing experience

More than just contract manufacturing

Product design & development

Legal, financial and insurance Services

Primary & secondary packaging

Fulfillment, logistics, warehousing

"Finally a digital contract manufacturing platform"

Wonnda is the fastest-growing B2B platform dedicated to private label and contract manufacturing of its kind. A fully digital sourcing experience built by entrepreneurs and a dedicated team, who have been there before.

Sign up for free and access our contract manufacturers

What is contract manufacturing?

Contract manufacturing is a form of outsourcing where a business contracts out the production of its products to a third-party manufacturer. This arrangement allows the hiring business to focus on core competencies such as design, branding, and distribution, while the contract manufacturer concentrates on the production process.

With contract manufacturing, businesses can achieve cost efficiencies, improved scalability, and faster time-to-market. The contract manufacturer provides the necessary facilities, labor, and equipment required for production, ensuring quality and compliance with industry standards. Through Wonnda, you gain access to a network of seasoned contract manufacturers, mainly located in Europe, who are adept at transforming your design specifications into finished products across a multitude of consumer goods sectors.

What is the difference between private label and contract manufacturing?

Contract manufacturing and private label manufacturing are two distinct approaches to product creation, each with its own set of advantages. Contract manufacturing is typically more tailored, starting from a unique design or specification provided by the hiring company. It offers deeper customization but can be time-consuming and costly. Private label, on the other hand, starts with a manufacturer’s existing product, which can then be modified and rebranded. This approach is generally quicker and may be more budget-friendly, but the level of customization is usually not as extensive as with contract manufacturing. The best option depends on your specific needs for customization, time, and budget.

Frequently asked questions

How does contract manufacturing work?

Contract manufacturing is when you use a third-party company to create, manufacture, or assemble your product. Some of these manufacturers can help from the start, working with you on designing your product and making sample versions to test before full production starts. Others concentrate just on the manufacturing part, meaning you should have your product completely designed and ready to go before you make a deal with them. Working with a contract manufacturer usually means you can save money, work more efficiently, and get your product out faster.

Why should I choose contract manufacturing?

Brands should not merely consider contract manufacturing but embrace it as a powerhouse for growth. It enables brands to streamline their operations, reduce lead times, and focus more on what they do best – whether it’s innovating new products, enhancing customer service, or expanding their market reach.

When should I use contract manufacturing?

If you’re trying out a new product or want to see how well a larger quantity sells, it’s smarter and cheaper to have another company make it for you. This way, you don’t spend a lot of money making it yourself before you’re sure it will sell well. If it does well, you can either decide to start making it in your own factory or keep working with the current manufacturer.

What are advantages and disadvantages of contract manufacturing?

Advantages

Reduced costs & increased profits

Contract manufacturing cuts down on overhead by outsourcing production, allowing companies to benefit from their partners’ technical knowledge and quality assurance while saving on equipment and labor costs.

Production expertise and quality control

Contract manufacturers offer specialized knowledge in materials and processes, and handle quality checks and defect replacements, streamlining production for their clients.

Ease of scaling

Outsourcing makes growing your business easier, especially in other countries, because the company you hire already knows people there, so you don’t have to deal with language issues or manage things from far away.

Disadvantages

Partner selection and trustworthiness

Choosing a reliable contract manufacturing partner can be challenging. Ensure they have a proven track record and solid references to avoid those who may miss deadlines, compromise on quality, or use poor materials, as such issues can be costly over time.

Protecting your intellectual property

There’s a risk of intellectual property theft in contract manufacturing. Although rare, some unethical manufacturers might misuse your proprietary information or even become direct competitors. It’s crucial to vet manufacturers carefully.

Assessing the financial aspects

While contract manufacturing saves on initial costs, in-house production may be cheaper per unit over time, once you’ve covered the initial equipment and setup expenses. Remember, contract manufacturing prices include additional costs like shipping and labor which can add up in the long run.

What are the types of contract manufacturing?

There are several kinds of agreements for contract manufacturing, but most of them fit into these four basic groups:

Private label manufacturing

A business outsources product design and manufacturing to a contract manufacturer, then sells the finished product under its own brand, benefiting from efficient production and design expertise.

Individual component manufacturing

In this scenario, the contract manufacturer’s role is to produce a single element that will be integrated into a complex end product. Their task is to precisely fabricate this particular part, which has been engineered during the product’s design phase.

Labor or service subcontracting

In this setup, a company hires a contract manufacturer for a specific part of the production. This is like a subcontractor working under a main contractor. It’s useful when making very complicated items because it can save money and speed up how long it takes to make something.

End-to-end manufacturing

In this kind of manufacturing, the company making the product gives the whole job to another company, including some of the design work. The contract manufacturer helps decide how the product should look and works closely with the company to figure things out. This is good for businesses that want to make something quickly and affordably without sacrificing quality.

How to select a contract manufacturer?

When vetting a contract manufacturer, prioritize their scalability, industry reputation, and ability to compare favorably with in-house production costs. Ensure their team has relevant experience, effective communication, and necessary certifications like ISO 9001:2015. Their location, the proficiency of their personnel, the adequacy of their equipment, and their overall financial stability are also crucial factors to consider for a successful manufacturing partnership.